目次 [非表示]

Do you have any problem ?

Kyoyu ‘s R&D Office have various solutions to the following issues.

- Want consultation about the required machining, machining accuracy and cost reduction.

- Want professional advice on procurement and best joining methods.

- Want response to both small-lot ordering and mass production.

- Want consultation about prototype production only with punch painting which shows the product image.

Our solutions

We will solve your problems in the following ways:

(1) Experienced and dedicated R&D staff directs production for machining and joining process

(2) Correspondence to prototype development per unit as well as mass production projects

(3) Correspondence to the specifications of the product you want to develop (e.g. appearance, size) as well as drafting and production

Our strengths

The solutions to the challenges we offer are supported by the following strengths:

(1) The knowledge and technical capabilities of the “Development Office” specializing in prototype development

(2) Good turning that corresponds from “small-lot ordering” to “mass production”

(3) “Integrated response” to procurement, processing, and inspection to ensure high quality

Past developments

We will introduce some of our experience so far. Details of each product can be found on the individual page.

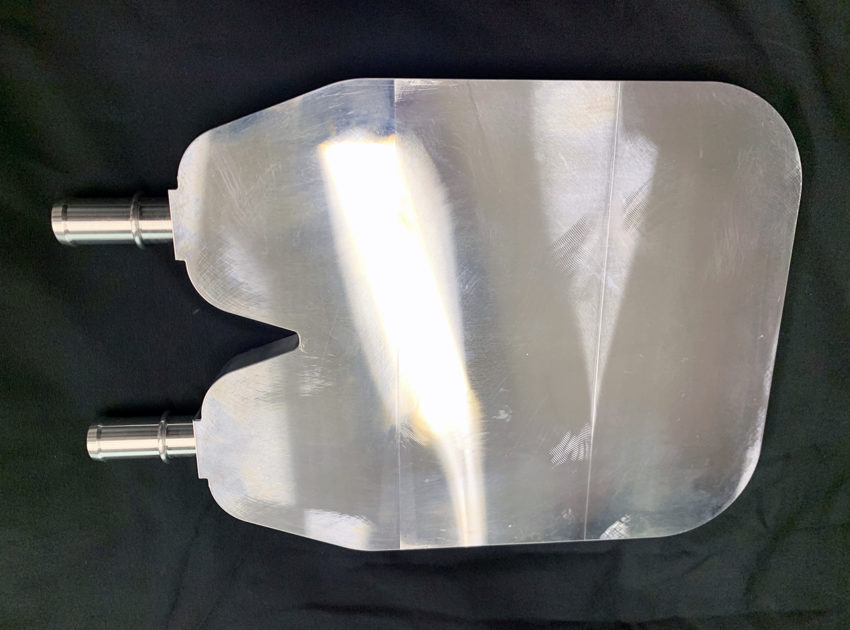

Cold plate

Aluminum Cold Plate (Prototype development case)

This case is a prototype development product that has been requested through the homepage. The water-cooled groove is processed into the main body, the lid is attached from the top, and then joined by FSW After joining with frictional stirring welding, the surface in contact with the heat source provides plane accuracy by machining The ...

Stainless Steel Cold Plate (circular shape)

After Tig welding with a water-cooled lid to the main body, distortion correction and machine finishing are performed. After that, the distortion correction is done again to get flatness. Material SUS304 , SUS316 Size Diameter 400mm~900mm Industry Vacuum Industry Processing details Machining Center, Tig Welding

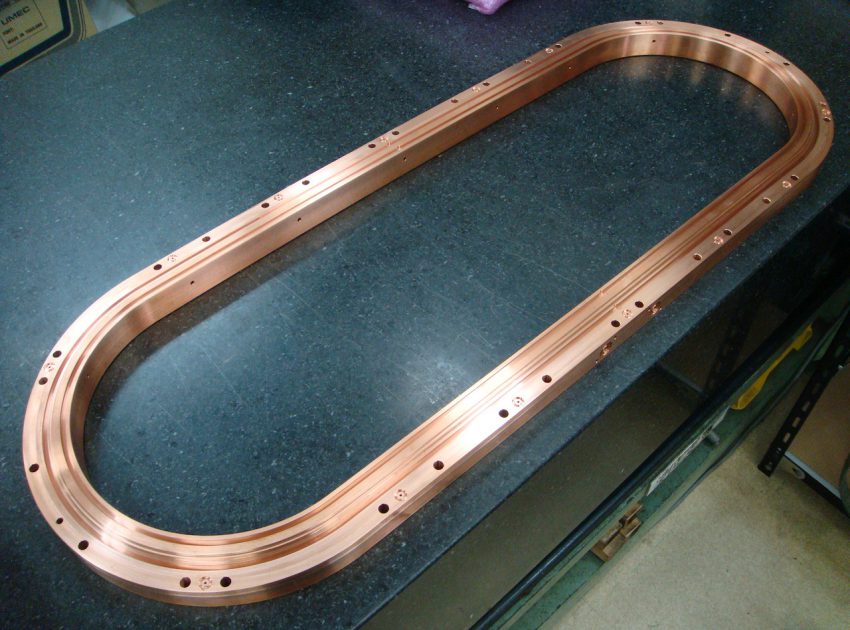

Pure Copper Cold Plate (Oval shape)

Pure copper is a difficult material, and warping occurs after cutting or joining. Therefore, in order to ensure the thickness of the water-cooled lid, distortion correction is necessary each time.It is also easy to scratch, so you need to pay close attention Material Pure Copper C1020 Size W300mm~400mm x L1000mm~1500mm Industry Vacuum Industry Processing details ...

Stainless Steel Cold Plate (rectangular shape)

After Tig welding with a water-cooled lid on the main body, the distortion correction is performed to get flatness. Material SUS304、SUS316 Size W200mm~400mm x L500mm~1500mm Industry Vacuum Industry Processing details Machining Center, Tig Welding

Backing plate

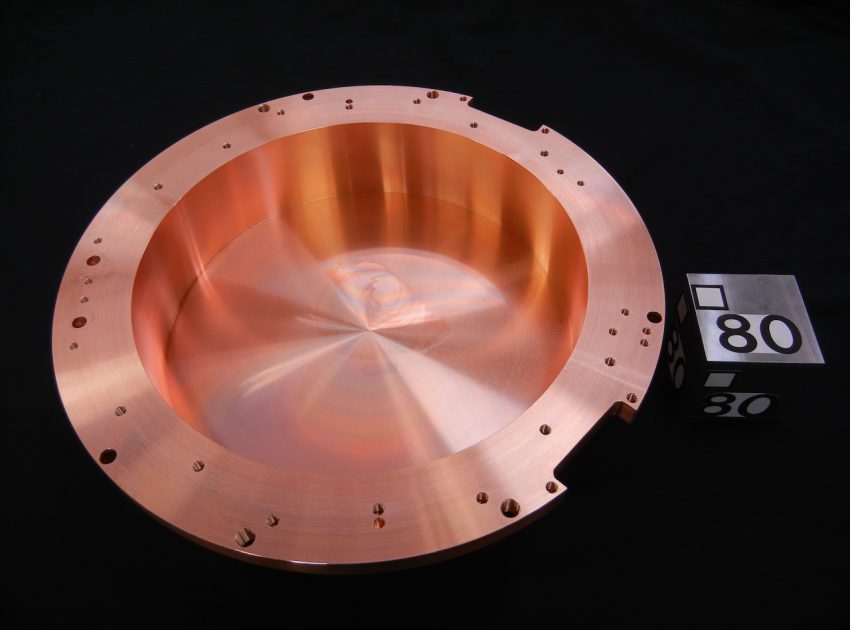

Sputtering Copper Backing Plate (Circular type)

This product has been requested through homepage. Surface of bonding-target is flat by 0.05. Material Copper Size Thickness 15 x Outer Diameter φ370 Industry Semiconductor Processing details Machinig-center,Lathe ,FSW

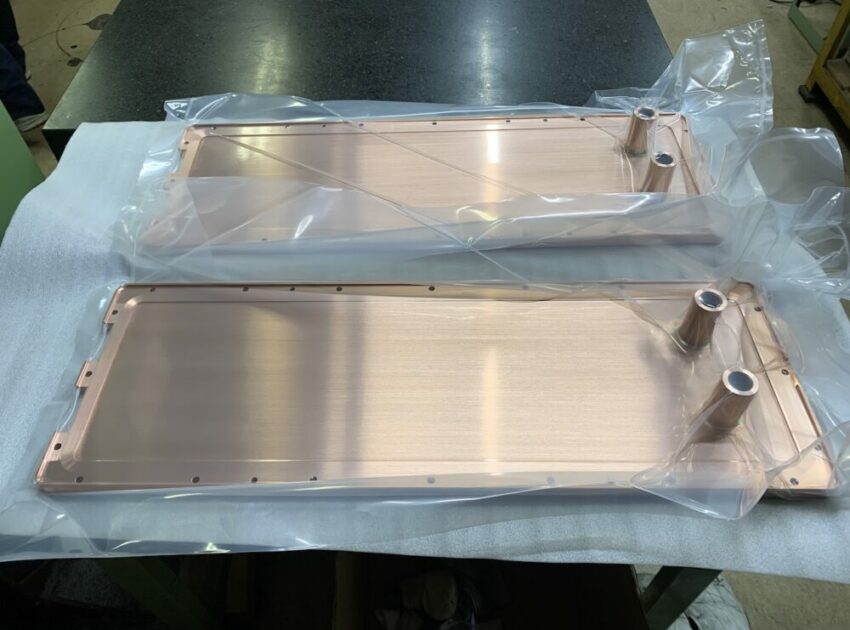

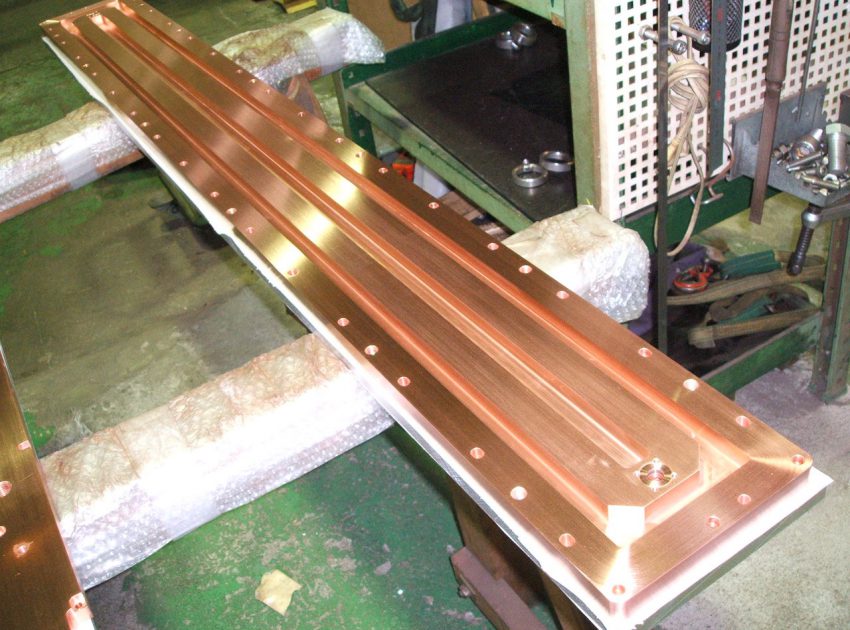

Pure Copper Backing Plate for Display Industry

This case shows one of products ordered by an overseas display manufacturer through the website. Product Name Backing plates Materials Pure copper (C1020) Size Width: 241 mm, Length: 691 mm, Thickness: 17 mm Industry/Field Displays Methods Machining center, FSW

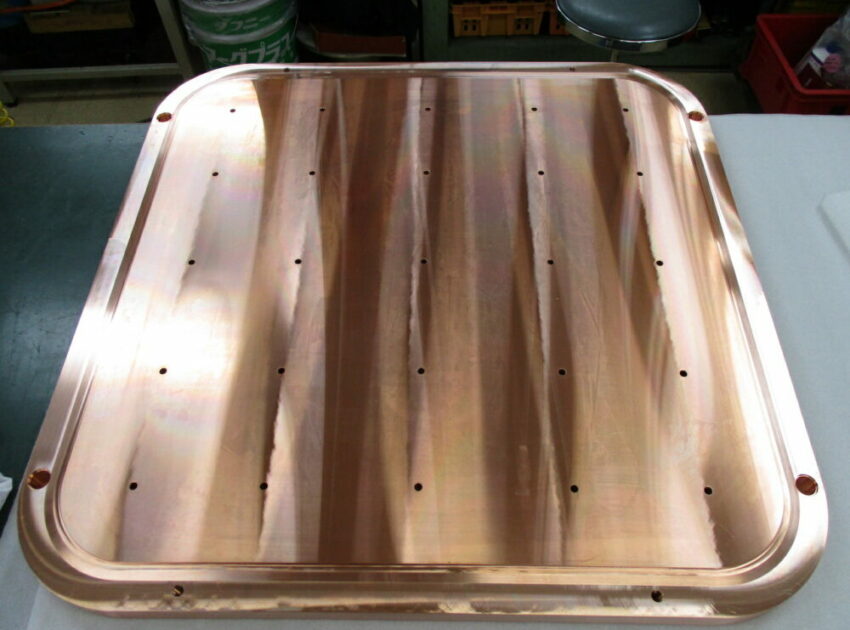

Pure Copper Backing Plate (Square shape)

This case is a prototype development product requested through the website. Materials Pure Copper(C1020) Size Width: 732 mm, Length: 732 mm, Thickness: 30 mm Industry/Field Semiconductors, Displays Methods Machining Center, Electron Beam Welding, FSW

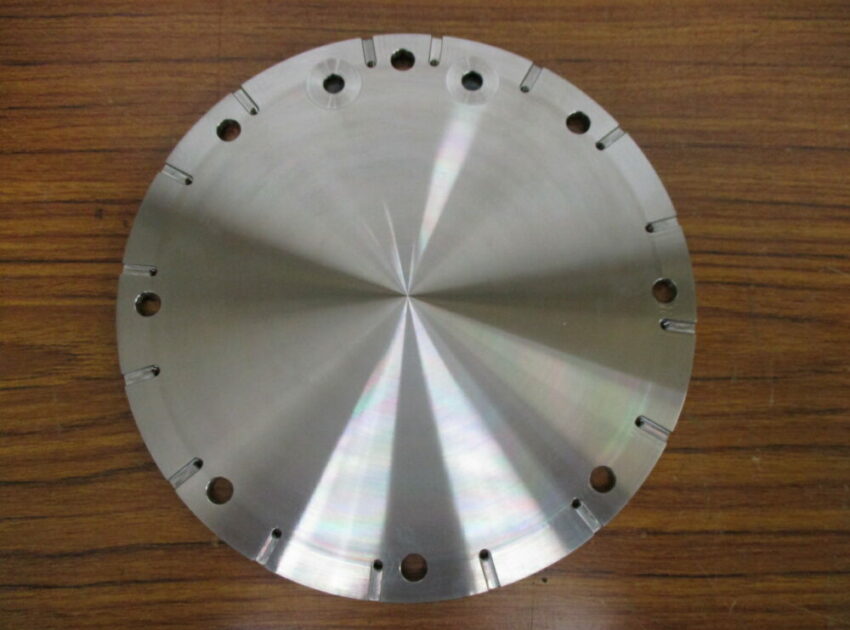

Stainless Steel Backing Plate (Circular shape)

This case is a prototype development product requested through the website. Materials Stainless steel (SUS304) Size Outer diameter: 220 mm, thickness: 8 mm Industry/Field Semiconductors, Displays Methods Machining Center, NC Lathe, TIG Welding

Pure Copper Backing Plate (Rectangular type)

Pure copper is a difficult material, and warping occurs after cutting or joining. Therefore, in order to ensure the thickness of the water-cooled lid, distortion correction is necessary each time. It is also easy to scratch, so you need to pay close attention. Material SUS304 , SUS316 Size W200mm~400mm x L500mm~1500mm Industry Vacuum Industry Processing ...

Pure Copper Backing Plate (Round shape)

Pure copper is a difficult material, and warping occurs after cutting or joining. Therefore, in order to ensure the thickness of the water-cooled lid, distortion correction is necessary each time.It is also easy to scratch, so you need to pay close attention. Material Pure Copper C1020 Size Around 500mm in dia Industry Vacuum Industry Processing ...

Vacuum chamber

Large Vacuum Chamber

This prototype chamber has been requested through homepage. Materials SUS304 Size W:1,190mm L:1,260mm H:460mm Industry/Field Semiconductor equipment Processing facilities Machining center, Tig welding, Pickling

Vacuum Chamber

Material SUS304 Size φ250mm x L260mm industry,field Univercity Lab processing,facility Machining center,Tig welding, Electric polishing comment This Prototype chamber has been requested through homepage and useful in the experiment of the well-known national univercity

Vacuum Chamber (AISI/ASTM304)

This prototype chamber has been requested through our website. Materials AISI/ASTM304 (SUS304) Size W500mm x L1,100mm x H350mm Industry/Field Semiconductor Manufacturing Processing facilities Machining center, Tig welding

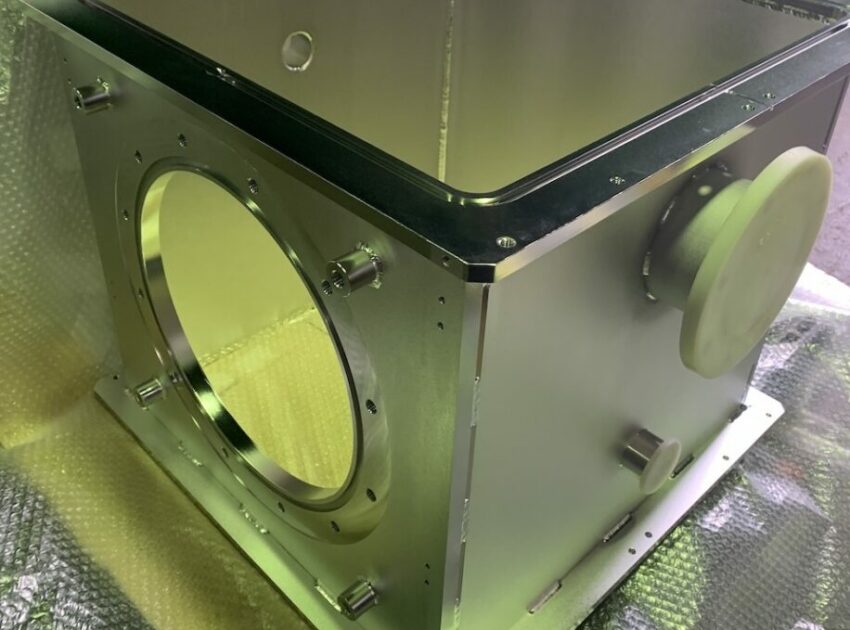

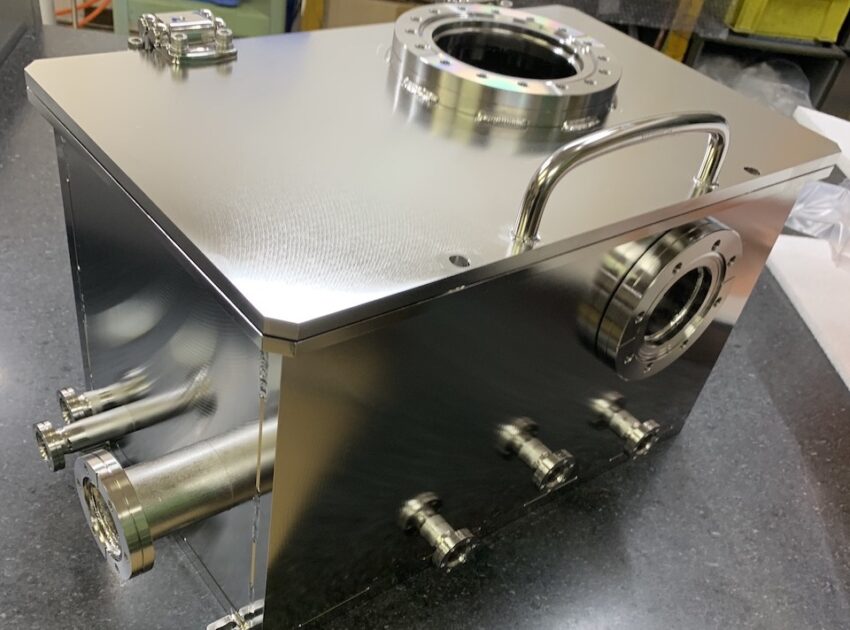

Stainless Steel Vacuum Chamber for Semiconductor Manufacturing

This case is a prototype development product requested through the website. Materials Stainless steel (SUS304) Size Width: 600 mm, Length: 600 mm, Height: 500 mm Industry/Field Semiconductor Manufacturing Processing facilities Machining centers, Horizontal boring machines, TIG welding

Stainless Steel Vacuum Chamber (Cylindrical shape)

This case is a prototype development product requested through the website. Material Stainless steel (SUS304) Size Outer diameter: φ400 mm, height: 400 mm Industry Semiconductors, Displays Processing details NC lathes, Machining centers, Horizontal boring machines, TIG welding

ICF Chamber (for University Lab)

This Prototype chamber has been requested through homepage and useful in the experiment of the well-known private university. Materials SUS304 Size W500mm x L500mm x H130mm Industry/Field University Lab Processing facilities Machining, Tig welding First, please feel free to contact us. We can handle a wide range of services from technical consultation on product production ...

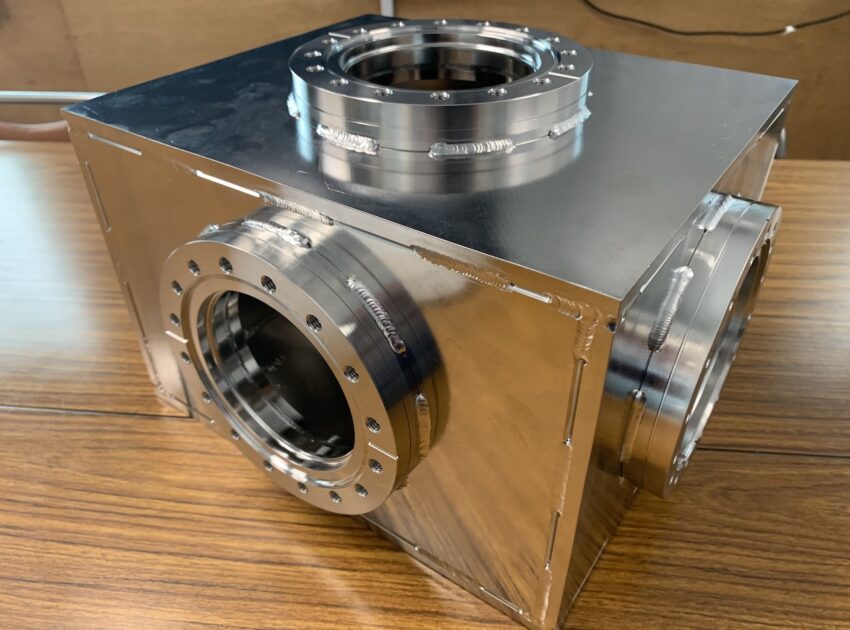

ICF Chamber for Semiconductor Manufacturing

This product is a prototype for experimental machines using ICF flanges. Materials SUS304 Size W250mm x L300mm x H200mm Industry/Field Semiconductor Manufacturing Processing facilities Machining, Tig welding

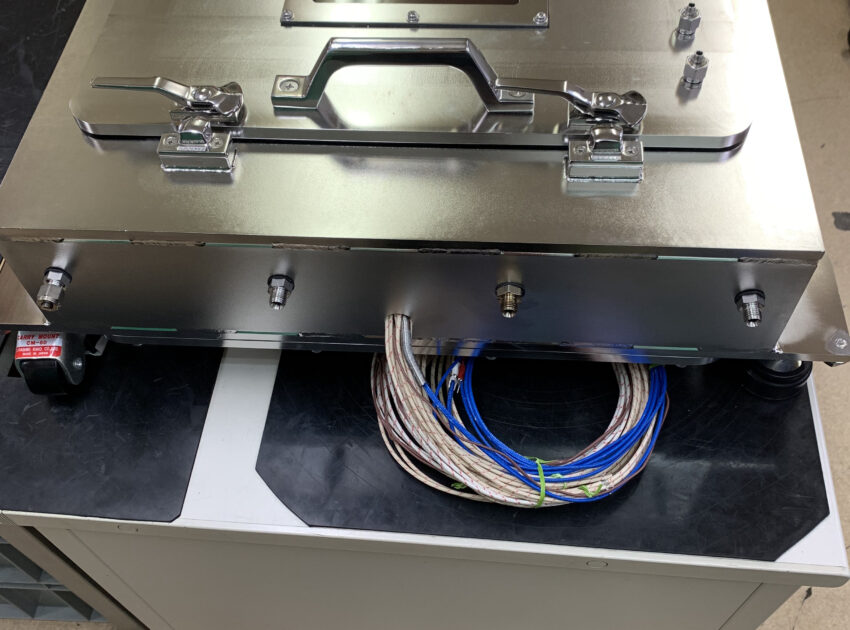

Vacuum Chamber (for semiconductor and display manufacturing)

This Prototype chamber has been requested through homepage and useful in annealing process. Materials SUS304 Size W500mm x L500mm x H130mm Industry/Field Machining center,Tig welding Processing facilities Machining center, Horizontal Boring Machine, Tig welder, General-purpose Lathe with NC

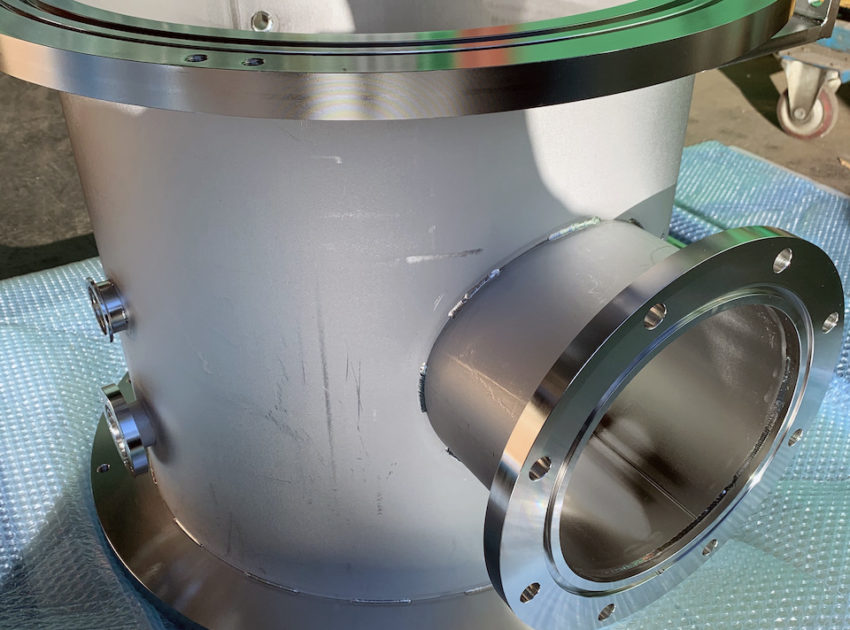

Stainless Steel Vacuum Chamber (cylindrical shape)

This case is a prototype development product that has been requested through the homepage. By adding a large lathe with NC to the machining process, it is possible to correspond to the cylindrical shape Materials SUS304 Size Outer diameter:φ625 mm、Height: 500mm Industry/Field Semiconductor, Flat Panel Display manufacturing equipment Processing facilities Machining center, Horizontal Boring Machine, ...

Work flow

From the time we receive your inquiry to the time of delivery, we will follow the flow below.

| Order | Process | Work details |

|---|---|---|

| 1 | Contact | For inquiries and requests for quotations, we ask you to contact us via the website inquiry form or by e-mail. |

| 2 | Meeting&Production Drawings | We will listen to your request, budget, desired delivery date, etc. In order to make man-hours and estimates, we will ask you to send us a production drawing. |

| 3 | Production Processing Diagram | We decide the processing method, man-hours, delivery date, estimate plan, etc., and make a production processing diagram. |

| 4 | Purchase Order | We will reconfirm the property information of P.O. in addition to confirming the some cautions about order. |

| 5 | Preparation of production instructions and bill of materials | ・Drafting Production Plannimg ・Material removal ・Machining Process set ・Sorting Equipment in chargeAfter confirming the above, we will make a production instruction and bill of materials. |

| 6 | Machinning・Welding | We handle a wide range of machining from plates to box chambers. |

| 7 | Test and Inspection | We thoroughly inspect products which will be delivered to the customers through dimensional inspection, leak testing, checking mill sheets, etc. |

| 8 | Packaging and cleaning work | We will clean the product and keep it clean, and then carefully pack it for delivery and shipment. |

| 9 | Shipping and delivery | We will ship the goods as instructed by P.O. |

First, please feel free to contact us.

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.