Vacuum chambers

Vacuum chambers are containers for vacuuming the interior and are the central components of sputtering, vacuum deposition equipment for Semiconductors, Liquid crystals, Organic EL.. and Medical and Pharmaceutical Sterilizers.

Our vacuum chambers

Kyoyu Seisakusho is good at in small and medium-sized square chambers that can be effectively installed even in a small space, mainly stainless steel, welding structure, non-mass production, and full custom-made, and has many supply records in vacuum chambers.

In companies that own large machines, the production of small and medium-sized chambers in small lots with a welding structure tends to be costly because the setup man-hours is spent extra. but our company uses the manufacturing know-how accumulated to thoroughly suppress costs and we have responded to customer requirements.

In addition to machining and welding, we are also working to enhance our services by cooperating with business partners to handle a wide range of procurement of materials and vacuum parts and surface treatment.

Production range

| Work material | Stainless steel (SUS304, SUS316), SS400 |

|---|---|

| Joining methods | Tig welding, Semi-automatic welding |

| Maximum size that can be manufactured | Around 1000mm square |

| Structure | Welded structure by Tig welding |

| Specifications | We will flexibly respond to the various specifications according to heating temperature and vacuum degree such as following conditions. - A chamber used in a low temperature range of about 150 ° C or less and that is sealed by the O-ring of the JIS flange - A chamber used in a medium temperature range of about 300 °C or less and that is sealed by a metal gasket of the ICF flange. - Without using a flange, it is also possible to process the O-ring groove directly on the chamber wall. |

| Remarks | In order to increase the degree of vacuum, we will respond to the necessary surface treatment and heat treatment. "Buffing , Electrolytic polishing" to improve the surface accuracy of the inner wall surface of the chamber "Baking treatment" to prevent the generation of residual gas in advance by gasifying gas molecules adhering to the inner wall of the chamber by cleaning or surface treatment by heat treatment. |

Product examples

Large Vacuum Chamber

This prototype chamber has been requested through homepage. Materials SUS304 Size W:1,190mm L:1,260mm H:460mm Industry/Field Semiconductor equipment Processing facilities Machining center, Tig welding, Pickling

Vacuum Chamber

Material SUS304 Size φ250mm x L260mm industry,field Univercity Lab processing,facility Machining center,Tig welding, Electric polishing comment This Prototype chamber has been requested through homepage and useful in the experiment of the well-known national univercity

Vacuum Chamber (AISI/ASTM304)

This prototype chamber has been requested through our website. Materials AISI/ASTM304 (SUS304) Size W500mm x L1,100mm x H350mm Industry/Field Semiconductor Manufacturing Processing facilities Machining center, Tig welding

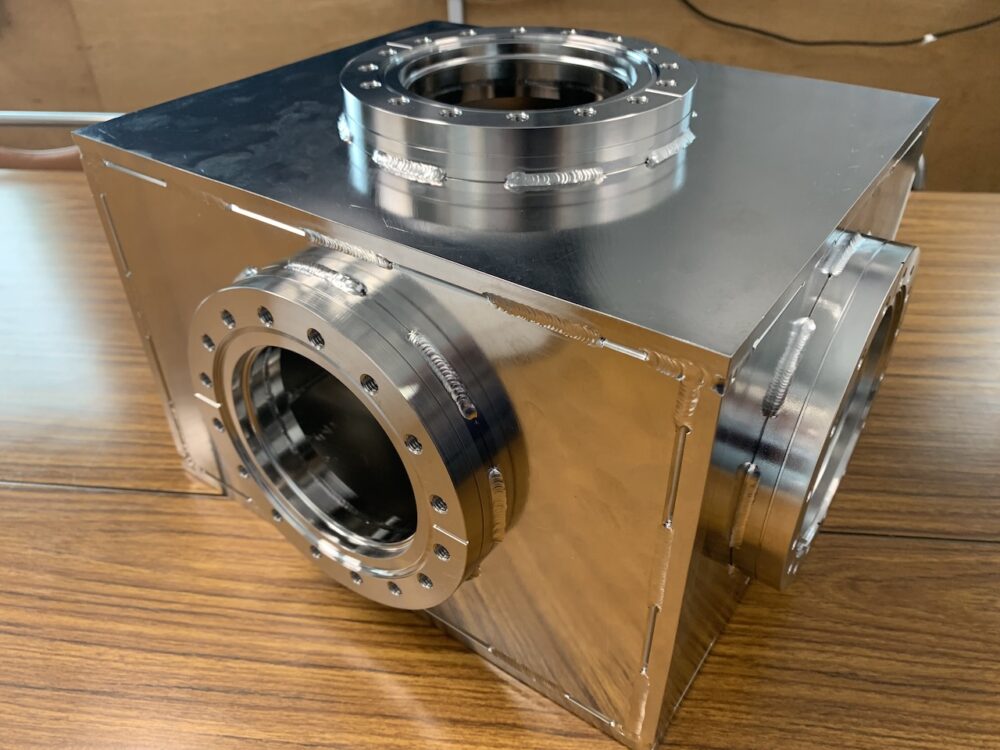

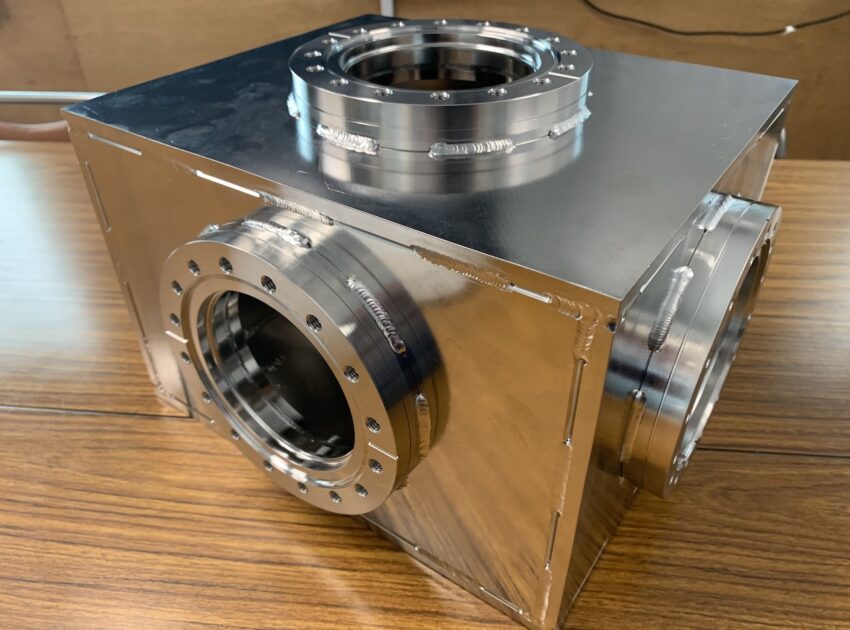

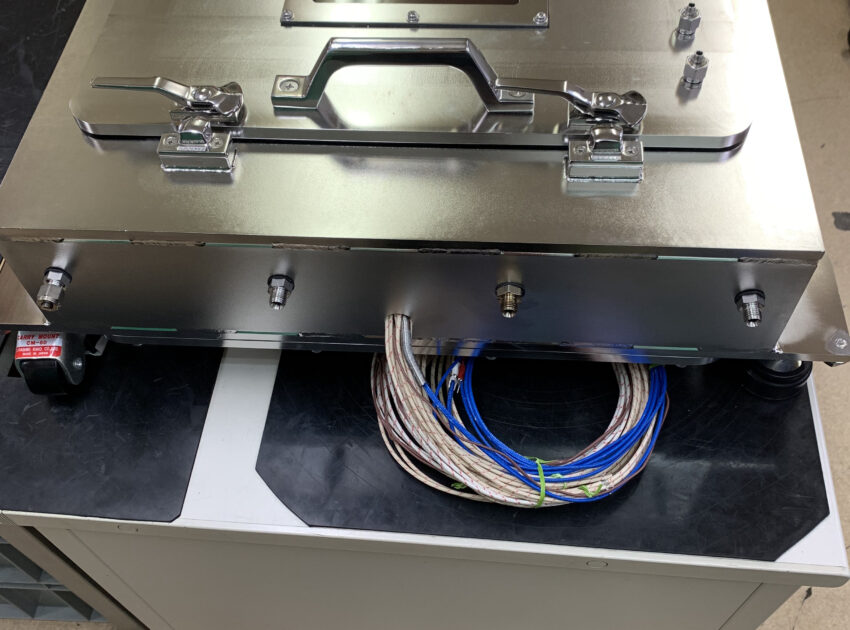

Stainless Steel Vacuum Chamber for Semiconductor Manufacturing

This case is a prototype development product requested through the website. Materials Stainless steel (SUS304) Size Width: 600 mm, Length: 600 mm, Height: 500 mm Industry/Field Semiconductor Manufacturing Processing facilities Machining centers, Horizontal boring machines, TIG welding

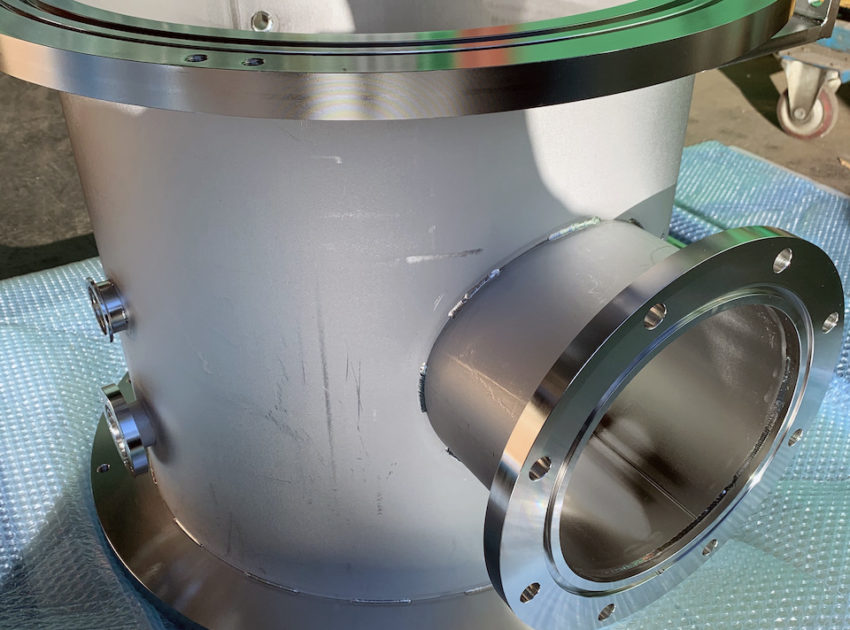

Stainless Steel Vacuum Chamber (Cylindrical shape)

This case is a prototype development product requested through the website. Material Stainless steel (SUS304) Size Outer diameter: φ400 mm, height: 400 mm Industry Semiconductors, Displays Processing details NC lathes, Machining centers, Horizontal boring machines, TIG welding

ICF Chamber (for University Lab)

This Prototype chamber has been requested through homepage and useful in the experiment of the well-known private university. Materials SUS304 Size W500mm x L500mm x H130mm Industry/Field University Lab Processing facilities Machining, Tig welding First, please feel free to contact us. We can handle a wide range of services from technical consultation on product production ...

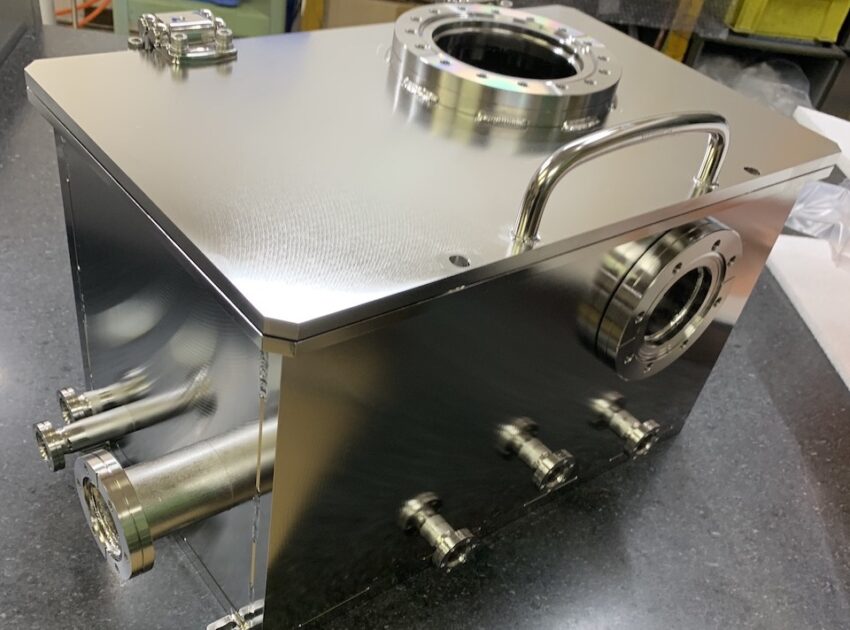

ICF Chamber for Semiconductor Manufacturing

This product is a prototype for experimental machines using ICF flanges. Materials SUS304 Size W250mm x L300mm x H200mm Industry/Field Semiconductor Manufacturing Processing facilities Machining, Tig welding

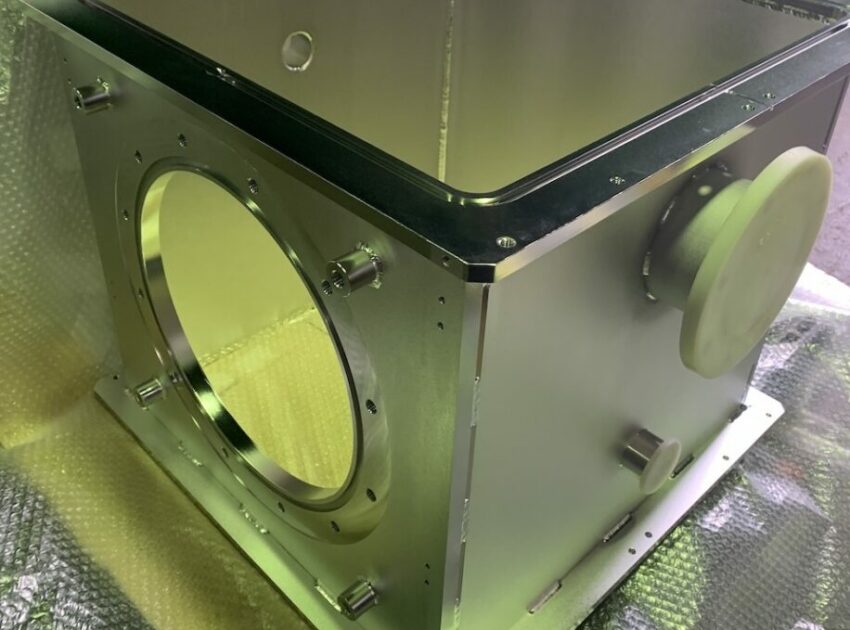

Vacuum Chamber (for semiconductor and display manufacturing)

This Prototype chamber has been requested through homepage and useful in annealing process. Materials SUS304 Size W500mm x L500mm x H130mm Industry/Field Machining center,Tig welding Processing facilities Machining center, Horizontal Boring Machine, Tig welder, General-purpose Lathe with NC

Stainless Steel Vacuum Chamber (cylindrical shape)

This case is a prototype development product that has been requested through the homepage. By adding a large lathe with NC to the machining process, it is possible to correspond to the cylindrical shape Materials SUS304 Size Outer diameter:φ625 mm、Height: 500mm Industry/Field Semiconductor, Flat Panel Display manufacturing equipment Processing facilities Machining center, Horizontal Boring Machine, ...

Questions about Custom Vacuum Chamber Manufacturing Service

What types of vacuum chambers do you develop?

We specialize in developing small and medium-sized square vacuum chambers, primarily made of stainless steel. Our chambers are custom-made to fit specific requirements and are ideal for tight spaces and specialized applications in semiconductor, liquid crystal, organic EL manufacturing, and medical sterilization.

What materials do you use for vacuum chamber construction?

We use high-quality materials such as SUS304 and SUS316 stainless steel, as well as SS400. These materials are chosen for their durability, low outgassing rates, and compatibility with vacuum environments.

How do you ensure the quality and performance of your vacuum chambers?

We adhere to strict quality control measures, including thorough testing for vacuum integrity using methods like leak detection and pressure decay tests. We also perform surface treatments such as buffing, electrolytic polishing, and baking treatment to enhance vacuum performance.

What customization options are available for your vacuum chambers?

We offer extensive customization options, including different chamber sizes and shapes, material selection, integration of O-ring grooves or metal gaskets, and specialized surface treatments. We tailor our solutions to meet your specific requirements, whether for low or medium temperature applications.

What is the typical lead time for a custom vacuum chamber project?

The lead time varies depending on the complexity and specifications of the project. Generally, the development and manufacturing process can take several weeks to a few months. We provide detailed timelines upon project assessment.

Do you provide design assistance and consultation?

Absolutely. Our experienced engineering team offers design assistance and consultation to ensure your vacuum chamber meets all technical and operational requirements. We collaborate with you from concept to final design.

How can I request a quote for a custom vacuum chamber?

You can request a quote by contacting us directly through our website or by phone. Provide us with your project details, including application requirements and specifications, and we will prepare a detailed proposal and quote.

Do you offer prototyping and testing services?

Yes, we offer prototyping and testing services to validate your design before full-scale production. This allows for thorough testing and adjustments to ensure the final product meets all specifications and performance criteria.

How do I start a custom vacuum chamber project with you?

To start a project, reach out to us through our contact form or call us directly. Provide your project details and requirements, and our team will work with you to develop a tailored solution and provide a comprehensive proposal.

Types of Vacuum Chambers by Shapes

Square (Rectangular) Vacuum Chambers

Square or rectangular chambers offer a practical design for maximizing internal space while fitting into small or irregularly shaped areas. These chambers are commonly used for their ease of fabrication and flexibility in accommodating various components.

Square or rectangular chambers offer a practical design for maximizing internal space while fitting into small or irregularly shaped areas. These chambers are commonly used for their ease of fabrication and flexibility in accommodating various components.

Applications: Ideal for semiconductor manufacturing, medical sterilization, and other applications requiring efficient use of space.

Advantages:

- Maximizes internal volume for equipment arrangement.

- Easier to integrate with other equipment and systems.

- Cost-effective due to simpler fabrication processes.

Challenges:

- Requires careful design to manage stress points and potential deformation under vacuum pressure.

Cylindrical Vacuum Chambers

Cylindrical chambers are favored for their uniform stress distribution and ease of achieving and maintaining a vacuum. These chambers are particularly effective for processes requiring symmetrical environments.

Cylindrical chambers are favored for their uniform stress distribution and ease of achieving and maintaining a vacuum. These chambers are particularly effective for processes requiring symmetrical environments.

Applications: Commonly used in vacuum deposition, sputtering, and plasma processing.

Advantages:

- Uniform wall thickness provides consistent performance.

- Symmetrical shape aids in maintaining a high-quality vacuum.

Challenges:

- Limited internal space for complex equipment arrangements compared to rectangular designs.

Custom-Shaped Vacuum Chambers

Custom-shaped chambers are designed to meet specific application requirements that standard shapes cannot accommodate. These chambers are tailored to fit unique process needs and spatial constraints.

Custom-shaped chambers are designed to meet specific application requirements that standard shapes cannot accommodate. These chambers are tailored to fit unique process needs and spatial constraints.

Applications: Specialized research and industrial processes, chemical vapor deposition (CVD), and unique etching processes.

Advantages:

- Tailored design to meet exact needs and specifications.

- Can integrate specialized ports, feedthroughs, and internal structures.

Challenges:

- Higher design and manufacturing costs.

- Complex maintenance and operation procedures.

First, please feel free to contact us.

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.