Stainless Steel Cold Plates

What are Stainless Steel Cold Plates?

Stainless steel cold plates are advanced thermal management solutions designed to provide efficient cooling for various components and systems. These cold plates are manufactured using stainless steel, a material known for its excellent corrosion resistance, strength, and durability.

Stainless steel cold plates are engineered to transfer heat from the source to a coolant, which can be liquid or air, ensuring optimal temperature regulation and reliable operation of components. They are widely used in industries with strict hygiene requirements or demanding environments, such as the food and beverage, medical and pharmaceutical, and electronics industries.

Production range

| Material | Aluminum, Stainless steel, Copper |

|---|---|

| Joining methods | Tig welding, Vacuum brazing, Electron beam welding (EBW), Friction stirring welding (FSW) |

| Maximum size that can be manufactured | Circular form:φ800mm Rectangular form:Width 1,000 mm、Length 2,000 mm |

| Structure | The jacket structure having grooves covering the lid from the above is main. |

| Shape | Compatible with various external shapes and complex waterway shapes |

| Specifications | All manufactured parts are custom-made with customer specifications |

Product examples

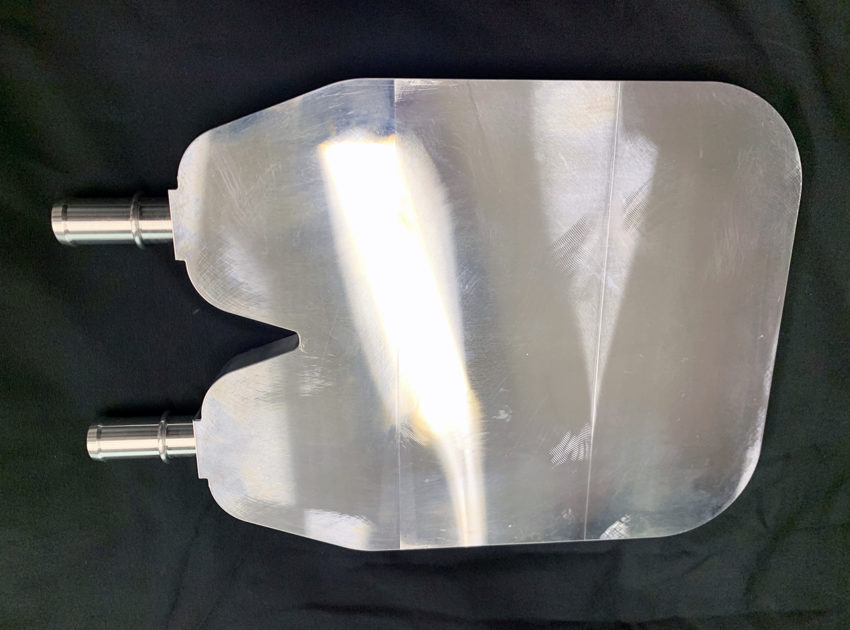

Round Stainless Cold Plate

After Tig welding with a water-cooled lid to the main body, distortion correction and machine finishing are performed. After that, the distortion correction is done again to get flatness. Material SUS304 , SUS316 Size Diameter 400mm~900mm Industry Vacuum Industry Processing details Machining Center, Tig Welding

Square Stainless Cold Plate

After Tig welding with a water-cooled lid on the main body, the distortion correction is performed to get flatness. Material SUS304、SUS316 Size W200mm~400mm x L500mm~1500mm Industry Vacuum Industry Processing details Machining Center, Tig Welding

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

Procution Process

The key to producing a good quality stainless steel jacketed thin water cooling plate is to correct any distortion or bends in the plate caused by welding.

Without this correction, even if the surface is ground to a smoothness, the distance between the water channel and the heat source contact surface will vary and the heat source will not be cooled evenly.

We use a specialized 100t press to correct the distortion and bends that occur after welding of the water cooler lid to ensure a level surface at the contact point of the heat source. If necessary, after correcting the distortion, we cut the surface. Here we show our processing process using a test piece.

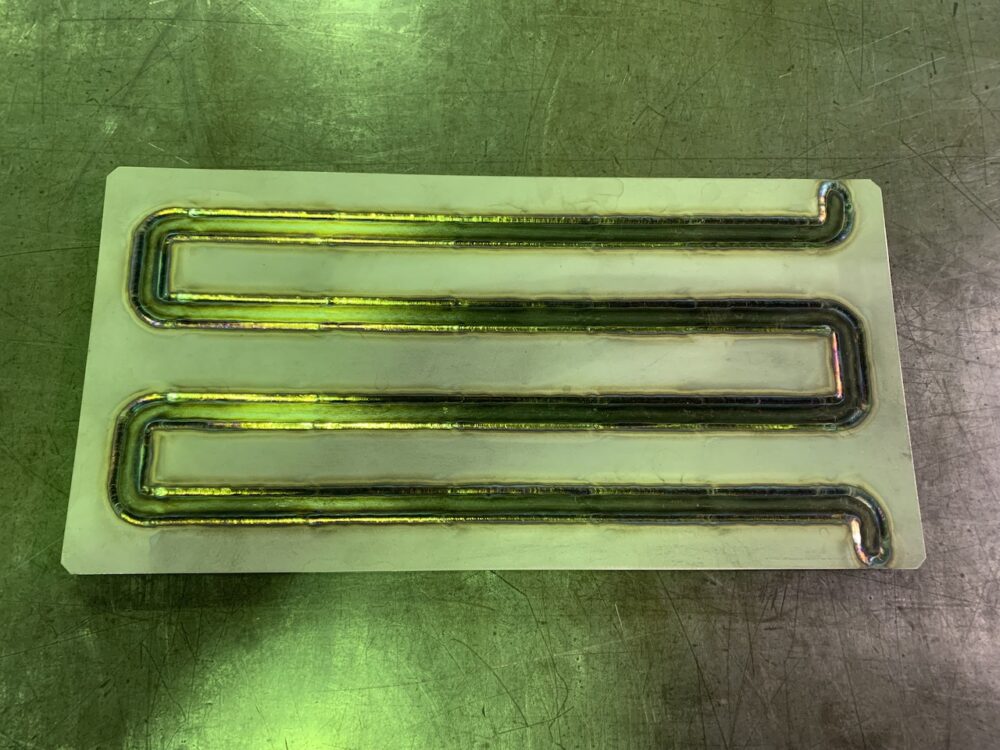

Process❶ Pre-weld processing

Cut water cooling groove and water cooled lid fitting stage in plate body (t10x200x400), t=1.5.

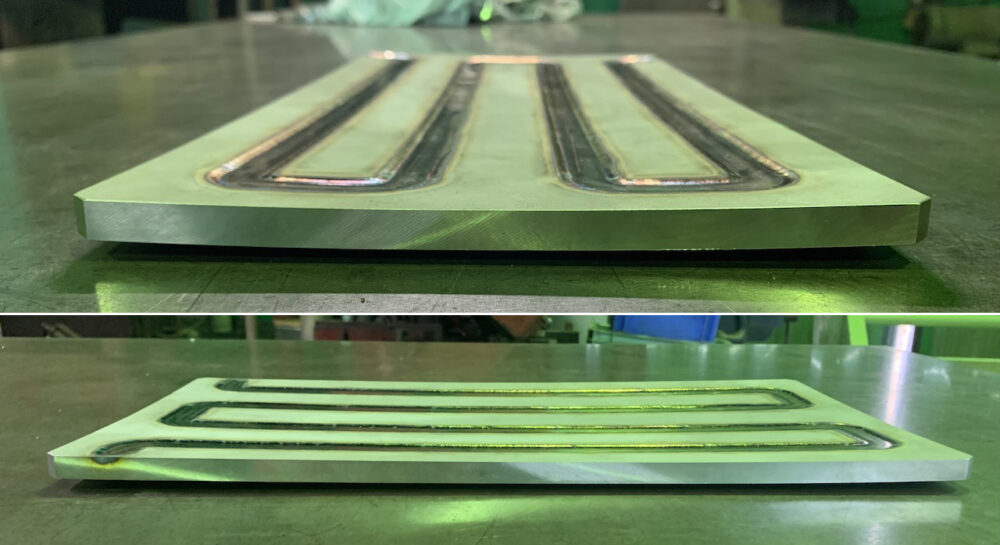

Process❷ Welding

Knock the lid into the processed fitting step.

Process❸ Tig weld lid to body all around.

Check the bowl-shaped bend on the surface plate.

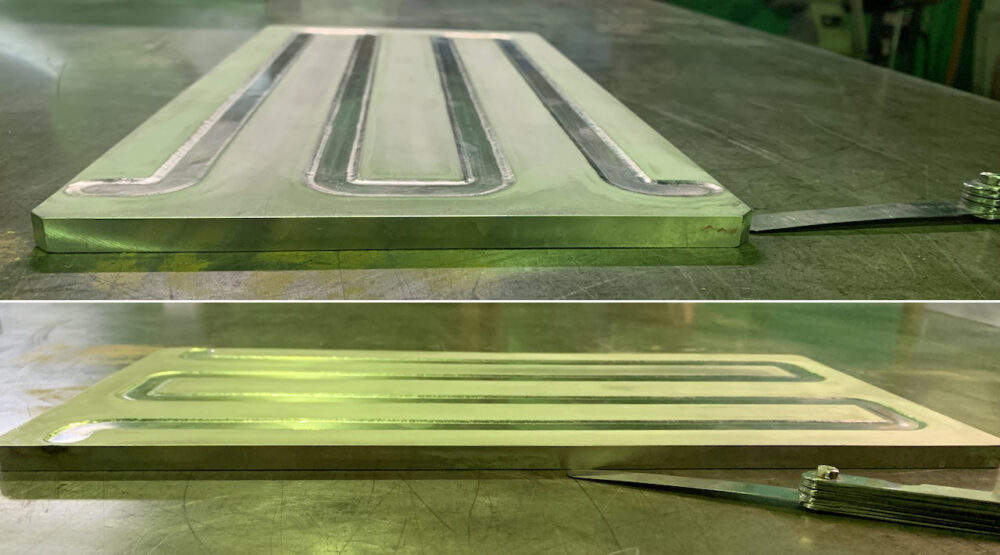

Process❹ Reduce distortion

Using a specialized press, repeatedly press the points on the surface that will be in contact with the heat source to correct the bends.

Process❺ Check the levelness

Check the flatness within 0.2 using a scimitar on the surface plate.

Stainless Steel Grades and Alloys for Cold Plates

There are several stainless steel grades and alloys commonly used in cold plate manufacturing, each offering unique properties and benefits. Here, we will discuss two popular stainless steel alloys:

304 Stainless Steel Alloy

This widely used stainless steel alloy offers a good balance of corrosion resistance, strength, and formability. It is commonly used in the production of stainless steel cold plates due to its overall performance and resistance to a wide range of environments.

316 Stainless Steel Alloy

This alloy is known for its excellent corrosion resistance, particularly in marine environments and against various chemicals. It offers superior resistance to pitting and crevice corrosion compared to 304 stainless steel, making it ideal for cold plates used in corrosive environments or those requiring high levels of corrosion resistance.

316 Stainless Steel Alloy

This alloy is known for its excellent corrosion resistance, particularly in marine environments and against various chemicals. It offers superior resistance to pitting and crevice corrosion compared to 304 stainless steel, making it ideal for cold plates used in corrosive environments or those requiring high levels of corrosion resistance.

Advantages and Benefits

Corrosion Resistance and Durability

Stainless steel cold plates offer several advantages and benefits, making them a popular choice for many thermal management applications. One of the primary benefits of stainless steel cold plates is their excellent corrosion resistance, which makes them suitable for use in harsh environments and applications with strict hygiene requirements. Stainless steel is also known for its durability and long service life, ensuring that cold plates made from this material will perform reliably over time.

Strength and Compatibility

Stainless steel cold plates exhibit high strength, which enables them to withstand the pressures and forces associated with demanding applications. Additionally, stainless steel is compatible with various coolants, including those that may be corrosive to other materials, such as aluminum or copper.

Thermal Performance

While stainless steel cold plates may not offer the same level of thermal conductivity as aluminum or copper cold plates, they still provide adequate cooling performance for many applications. In some cases, the superior corrosion resistance and compatibility with various coolants may make stainless steel cold plates the preferred choice, despite the trade-off in thermal conductivity.

Comparing Stainless Steel Cold Plates with Other Materials

Stainless steel cold plates are often compared to other materials, such as aluminum and copper, each with its unique set of advantages and disadvantages:

Aluminum Cold Plates

This case is a prototype development Aluminum cold plates are lighter and more affordable than copper cold plates but typically have lower thermal conductivity. This makes them suitable for applications where weight and cost are more important than maximum heat transfer performance. However, in high-performance cooling systems, the superior thermal conductivity of copper is often preferred.

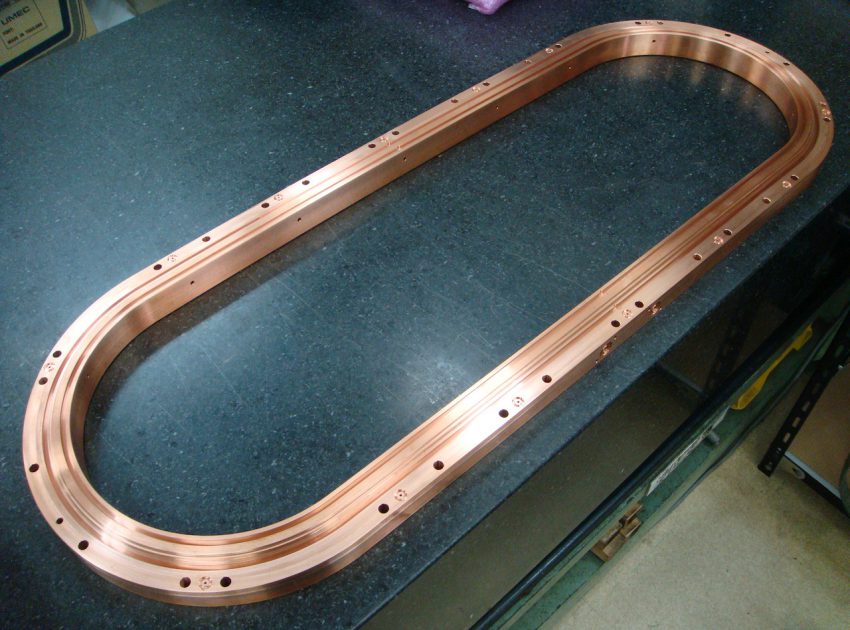

Copper Cold Plates

Copper cold plates offer superior thermal conductivity compared to aluminum cold plates, making them ideal for high-performance cooling applications. However, copper cold plates are typically heavier and more expensive than their aluminum counterparts.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

Applications of Stainless steel Cold Plates

Stainless steel cold plates are used in a wide range of applications across various industries, such as:

Electronics and Semiconductor Cooling

Stainless steel cold plates are also used in the electronics and semiconductor industries for cooling power electronics, laser systems, and other heat-sensitive components. While not as thermally conductive as copper or aluminum cold plates, stainless steel cold plates can still provide adequate cooling performance in applications where corrosion resistance and compatibility with various coolants are more important considerations.

Food and Beverage Industry

Stainless steel cold plates are widely used in the food and beverage industry for cooling processes, equipment, and storage systems. Their excellent corrosion resistance and compatibility with various coolants make them ideal for maintaining strict hygiene standards and preventing contamination.

Medical and Pharmaceutical Industry

In the medical and pharmaceutical industry, stainless steel cold plates are employed for cooling critical components and equipment , such as imaging systems, laboratory instruments, and temperature-sensitive pharmaceutical products. Their corrosion resistance and ability to withstand harsh cleaning and sterilization processes make them an ideal choice for these demanding applications.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

FAQs about Stainless Steel Cold Plate

How do stainless steel cold plates compare to aluminum and copper cold plates in terms of thermal conductivity?

Stainless steel cold plates have lower thermal conductivity compared to aluminum and copper cold plates. However, they offer superior corrosion resistance and are compatible with various coolants, making them suitable for applications where these factors are more important than the highest possible heat transfer performance.

Can stainless steel cold plates be customized for specific applications?

Yes, stainless steel cold plates can be customized to meet specific design requirements and performance objectives. Customization options may include optimizing the geometry and dimensions for improved heat dissipation, incorporating specialized coolant flow paths, or integrating mounting features to facilitate installation. By working closely with manufacturers and suppliers, engineers can develop customized stainless steel cold plate solutions that meet the unique needs of their applications.

Are stainless steel cold plates suitable for use with corrosive coolants?

Stainless steel cold plates are compatible with various coolants, including those that may be corrosive to other materials, such as aluminum or copper. However, it is essential to consult with cold plate manufacturers and experts to determine the most suitable material and design for specific applications, taking into account the coolant's properties and potential compatibility issues.

Can stainless steel cold plates be used in high-temperature applications?

Stainless steel cold plates are suitable for many high-temperature applications, but their performance may be limited by the material's properties, such as thermal expansion and oxidation resistance. For very high-temperature applications, alternative materials or specialized designs may be more appropriate. It is essential to consult with cold plate manufacturers and experts to determine the most suitable material and design for high-temperature applications.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.