- This case is a prototype development product that has been requested through the homepage.

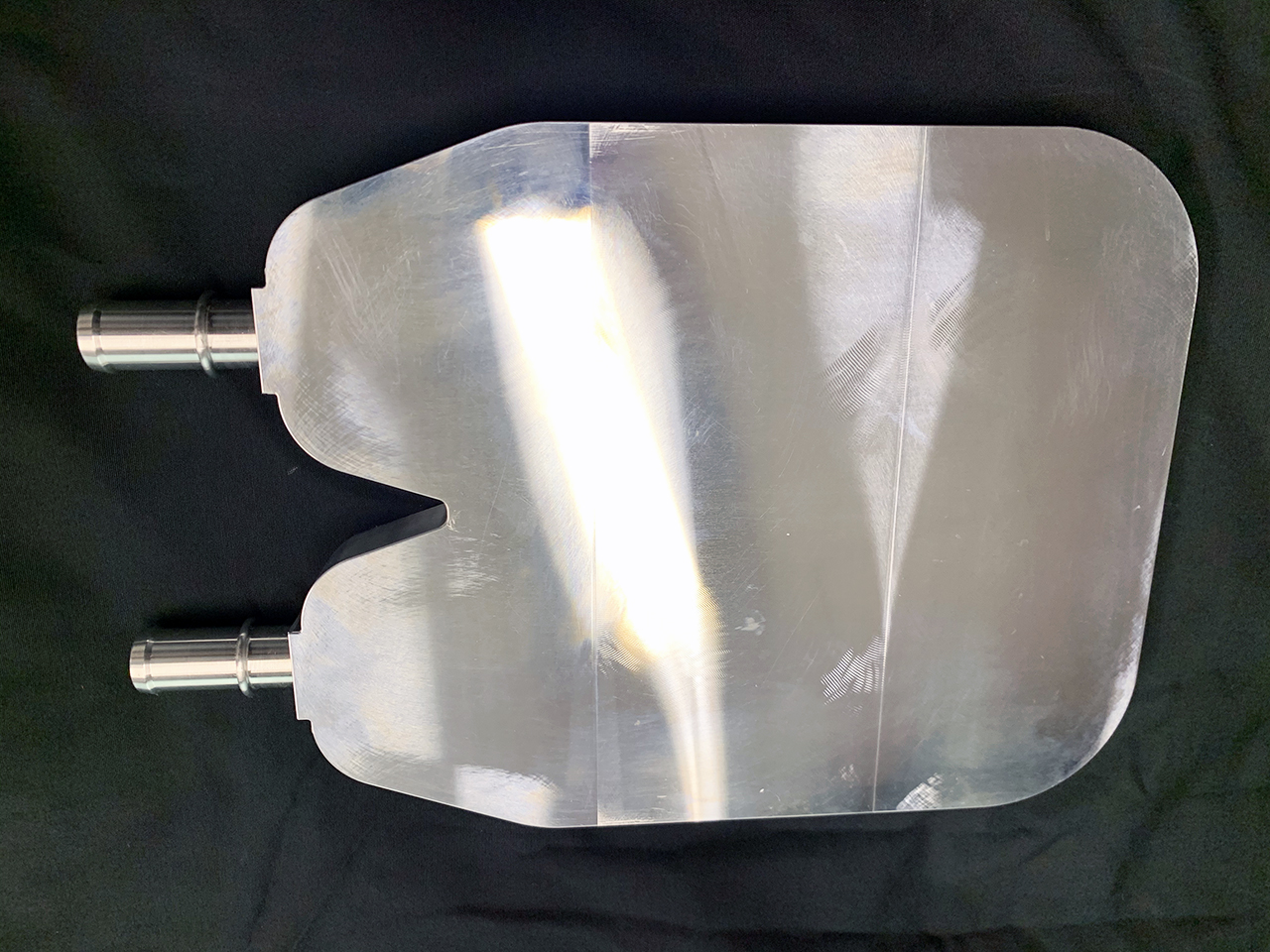

- The water-cooled groove is processed into the main body, the lid is attached from the top, and then joined by FSW

- After joining with frictional stirring welding, the surface in contact with the heat source provides plane accuracy by machining

- The inlet and outlet openings of the coolant are processed using special tools

- Conventionally, the brass mouth is lowered to the main body.

- The purpose of the in-one processing is (1) corrosion prevention by joining aluminum and brass (2) preventing chips, etc. generated during hole processing of the mouth wall from entering the waterway.

| Materials | A6061 |

|---|---|

| Size | 10-25mm thickness, 60-180 width, 60-270 length |

| Industry/Field | Medical equipment Automobile related |

| Methods | Machining center, Tig welding |