Cooper Cold Plates

What Are Cooper Cold Plates?

Copper cold plates are advanced thermal management devices specifically engineered for efficient cooling of components and systems. They are designed to dissipate heat generated by high-power electronic devices, machinery, and other heat-sensitive equipment.

These cold plates are made of copper, a metal known for its outstanding thermal conductivity and heat transfer properties. By utilizing copper, cold plates can effectively transfer heat from the source to a coolant, such as liquid or air, ensuring optimal temperature regulation and reliable operation of components. Copper cold plates are commonly found in industries such as electronics, high-performance computing, renewable energy, aerospace, and defense.

Production range

| Material | Aluminum, Stainless steel, Copper |

|---|---|

| Joining methods | Tig welding, Vacuum brazing, Electron beam welding (EBW), Friction stirring welding (FSW) |

| Maximum size that can be manufactured | Circular form:φ800mm Rectangular form:Width 1,000 mm、Length 2,000 mm |

| Structure | The jacket structure having grooves covering the lid from the above is main. |

| Shape | Compatible with various external shapes and complex waterway shapes |

| Specifications | All manufactured parts are custom-made with customer specifications |

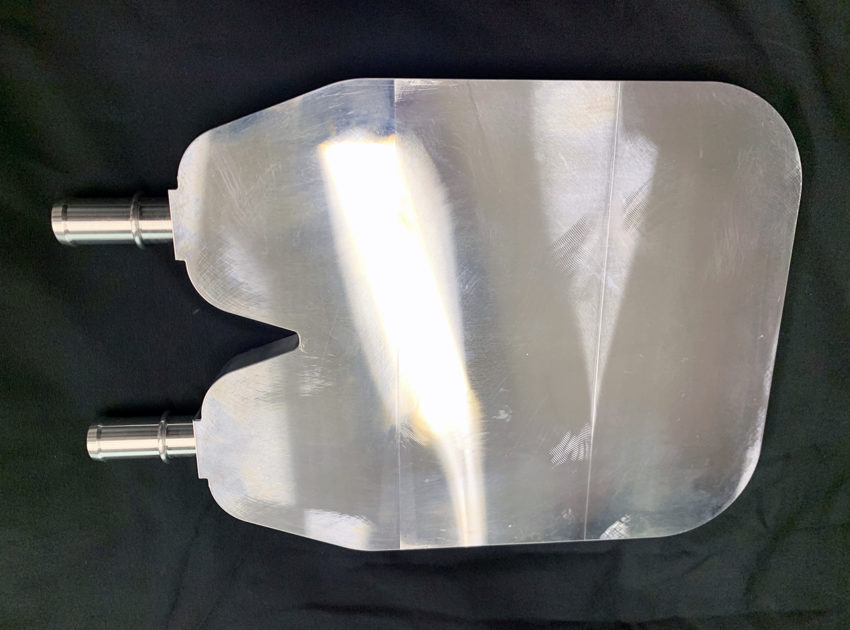

Product example

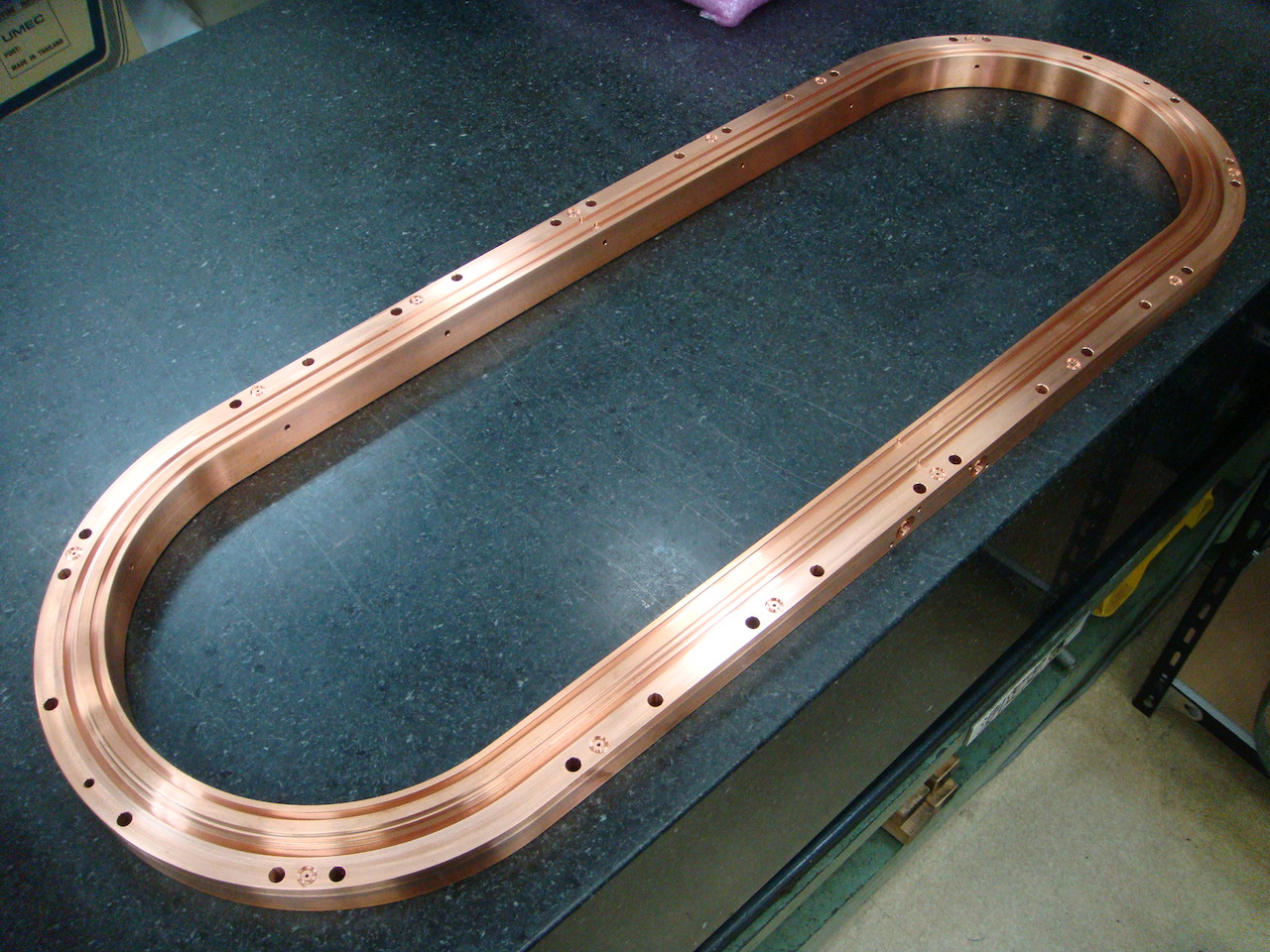

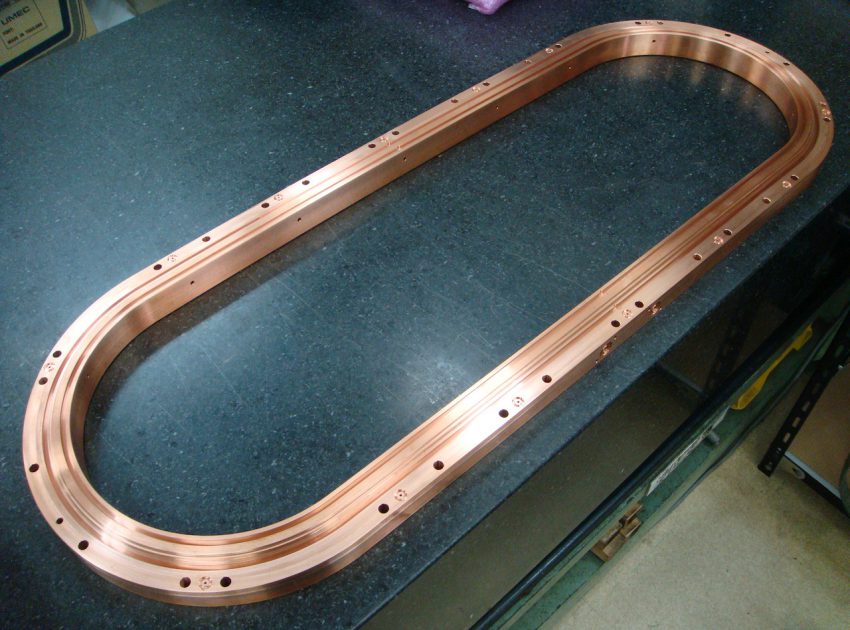

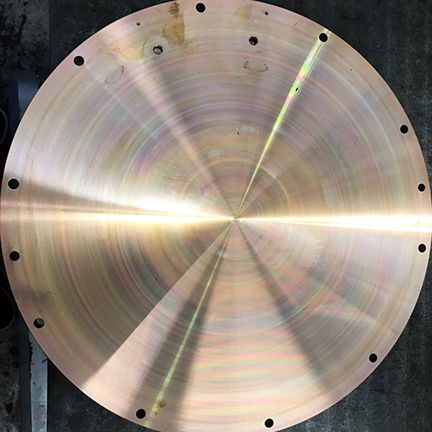

Copper Cold Plate

Pure copper is a difficult material, and warping occurs after cutting or joining. Therefore, in order to ensure the thickness of the water-cooled lid, distortion correction is necessary each time.It is also easy to scratch, so you need to pay close attention Material Pure Copper C1020 Size W300mm~400mm x L1000mm~1500mm Industry Vacuum Industry Processing details ...

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

Procution Process

| Product | Customized Liquid Cold plate |

|---|---|

| Material | Copper |

| Processing method | Friction stir welding (FSW), Machining center |

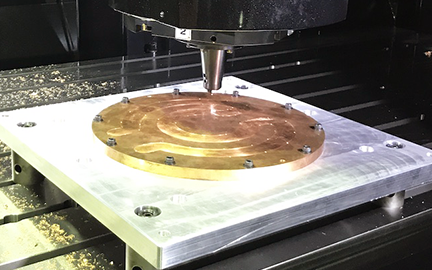

Process❶ Before welding (Preparation)

- On the main plate, the groove where the cooling water flows and the fitting part of the same depth as the thickness of the lid are machined.

- Cover the joint groove with a lid (tapping so that there is no step on the bonding surface)

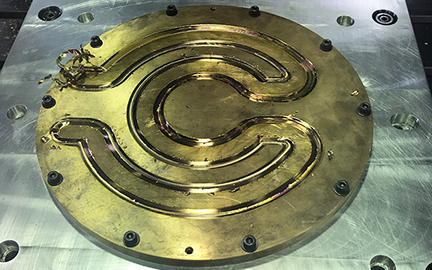

Process❷ FSW processing

At the time of joining, metal scrap is discharged around the joint by pressing force (1.2t) from the top of the tool and the force moving sideways. As shown in the image below, the joint marks by the tool remain (slightly discoloration due to frictional heat)

Process❸ After Finishing

1mm cutting from joined end face

The boundary of the joint cannot be determined as shown in the image below, and it can be understood that the main plate and the lid are integrated.

Copper Grades and Alloys for Cold Plates

Copper cold plates are available in various grades and alloys, each offering distinct properties and advantages.

Pure Copper (C11000)

Pure copper (C11000) is a highly conductive, oxygen-free copper grade that is ideal for demanding cooling applications. This grade provides excellent thermal conductivity and is often used in high-performance computing systems, semiconductor cooling, and other heat-sensitive equipment.

Advantages and Benefits

Copper cold plates offer numerous advantages and benefits over other materials, making them a preferred choice for many applications.

High Thermal Conductivity

Firstly, copper has excellent thermal conductivity, which allows for rapid and efficient heat transfer. This makes copper cold plates ideal for cooling high-power electronic devices and components that generate significant heat.

Reliable Cooling Perfomance

Secondly, copper cold plates provide reliable cooling performance, ensuring the stability and longevity of sensitive equipment. Additionally, copper offers natural corrosion resistance, which further enhances the durability and longevity of copper cold plates.

Compact Design

The high thermal conductivity of copper cold plates also contributes to their compact design. With more effective heat transfer, copper cold plates can be designed with smaller dimensions, making them suitable for space-constrained applications.

Customizable

Furthermore, copper cold plates can be customized to meet specific design requirements and performance objectives, such as increased surface area for enhanced heat dissipation or specialized geometries for optimal coolant flow.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

Applications of Copper Cold Plates

Copper cold plates are widely used across various industries and applications

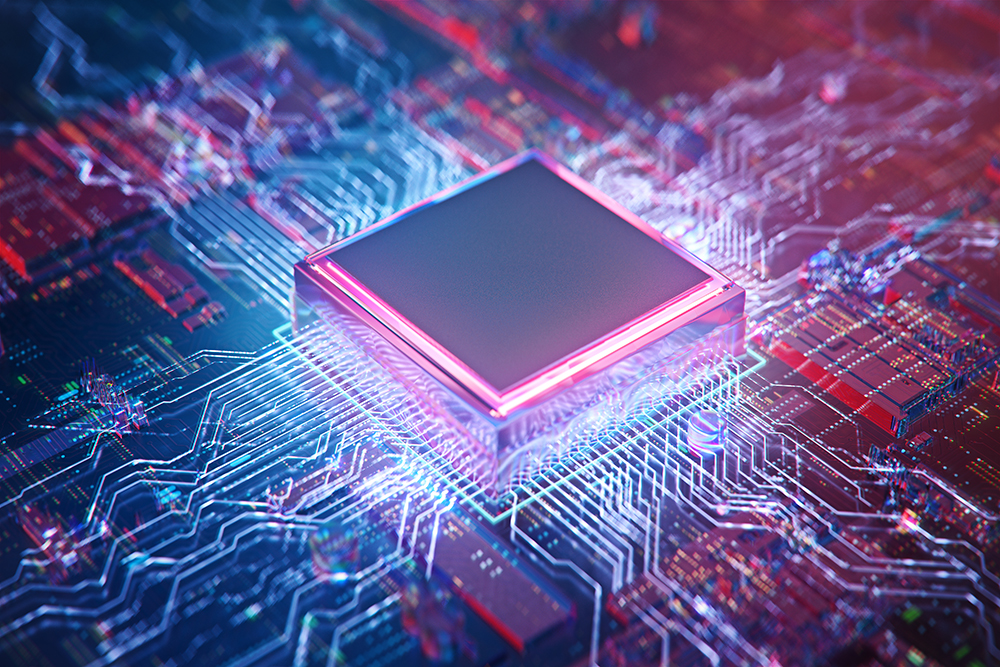

Electronics and Semiconductor Cooling

Copper cold plates play a critical role in dissipating heat from high-power electronic devices, integrated circuits, and semiconductors. By efficiently transferring heat away from these components, copper cold plates help maintain optimal operating temperatures and prevent thermal-related failures.

High-Performance Computing Systems

In data centers and other high-performance computing environments, copper cold plates are used to cool processors, graphics processing units (GPUs), and other heat-generating components. By ensuring effective cooling, copper cold plates contribute to the stability, performance, and energy efficiency of these systems.

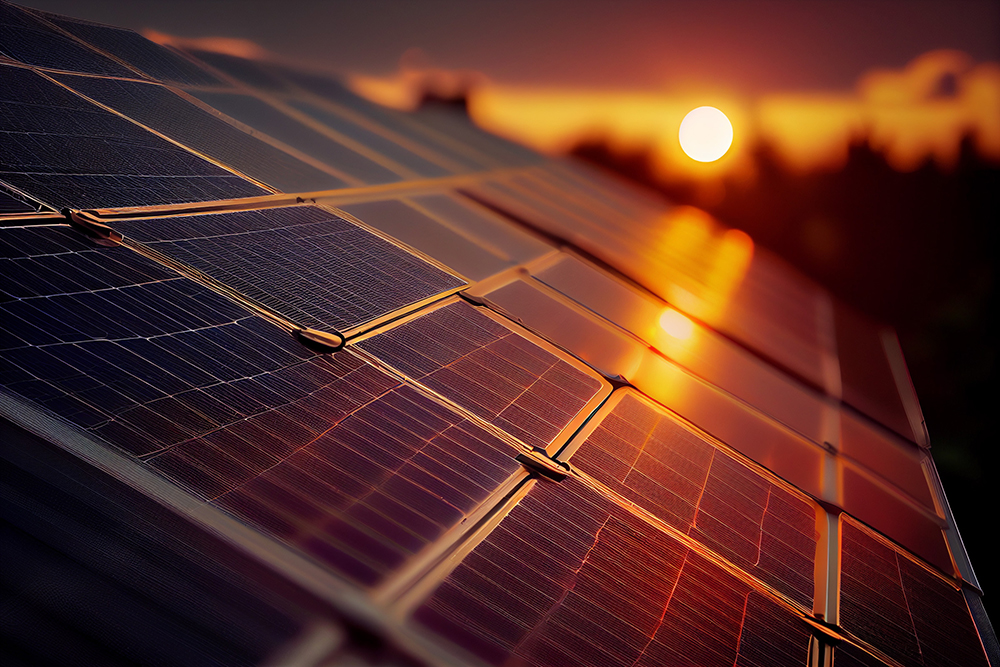

Renewable Energy Systems

Copper cold plates are utilized in cooling systems for solar power inverters, fuel cells, and other renewable energy applications. These systems often generate considerable heat during operation, and efficient cooling is essential for maintaining performance, reliability, and service life. Copper cold plates provide the necessary thermal conductivity to dissipate heat effectively, ensuring optimal functioning of these renewable energy systems.

Aerospace and Defense

In aerospace and defense applications, copper cold plates are employed for cooling mission-critical systems, avionics, and other heat-sensitive components. With their excellent thermal performance and corrosion resistance, copper cold plates ensure the reliable operation of these systems, even in harsh and demanding environments.

Industrial Equipment Cooling

Copper cold plates are also used in various industrial applications, such as cooling hydraulic systems, power electronics, and high-power laser systems. By providing efficient heat dissipation, copper cold plates help maintain the performance and extend the life of these essential industrial systems.

Comparing Copper Cold Plates with Other Materials

Copper cold plates are often compared to other materials, such as aluminum and stainless steel, each with its unique set of advantages and disadvantages.

Aluminum Cold Plates

This case is a prototype development Aluminum cold plates are lighter and more affordable than copper cold plates but typically have lower thermal conductivity. This makes them suitable for applications where weight and cost are more important than maximum heat transfer performance. However, in high-performance cooling systems, the superior thermal conductivity of copper is often preferred.

Stainless Steel Cold Plates

Stainless steel cold plates provide excellent corrosion resistance but have lower thermal conductivity compared to aluminum cold plates. While stainless steel is suitable for applications that require exceptional resistance to corrosion and chemical attack, it may not be the best choice for applications where high heat transfer performance is crucial.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.

FAQs about Copper Cold Plates

Are copper cold plates more expensive than other materials?

Copper cold plates tend to be more expensive than aluminum or stainless steel cold plates due to the higher cost of copper as a raw material. However, the superior thermal conductivity of copper often justifies the added expense, particularly in high-performance applications where effective cooling is essential.

How do copper cold plates perform in corrosive environments?

Copper is naturally corrosion-resistant, making copper cold plates suitable for use in a variety of environments. However, in highly corrosive environments or those with specific chemical exposure, it may be necessary to consider additional protective measures, such as surface treatments or coatings, to further enhance the corrosion resistance of copper cold plates.

Can copper cold plates be customized for specific applications?

Yes, copper cold plates can be customized to meet specific design requirements and performance objectives. Customization options may include optimizing the geometry and dimensions of the cold plate for enhanced heat dissipation, incorporating specialized coolant flow paths, or integrating mounting features to facilitate installation. By working closely with manufacturers and suppliers, engineers can develop customized copper cold plate solutions that meet the unique needs of their applications.

Connect with Our Dedicated Team

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.