What is “Friction Stirring Welding”

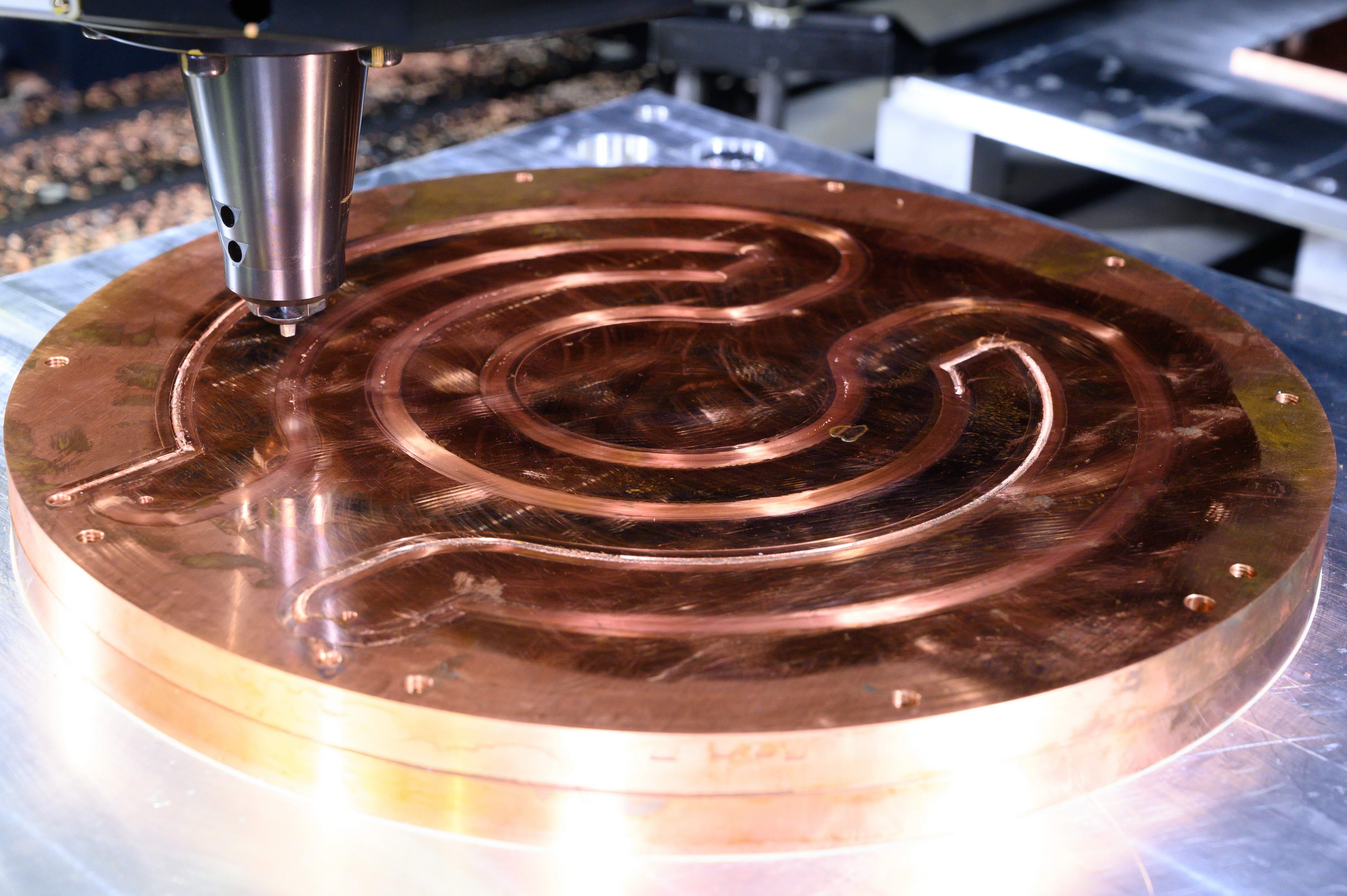

Friction stirring welding is a bonding method that integrates multiple parts by rotating a cylindrical tool with a protrusion at the tip, simultaneously pressing it with a strong force to soften the main material with frictional heat (below the melting point of the material), and kneading it by plastic flow. In our equipment, by pressing with a force of 1.2 tons, it penetrates the junction to a depth of 4 to 6 mm. It is also written as FSW by taking the initials of “Friction Stirring Welding”.

FSW, which is classified as a solid-phase bond, is heated and softened in a solid state without melting, and then pressurized and bonded. In our equipment, it is possible to machine from cutting process to FSW consistently on the same machine, so there is no need to move and transport workpieces, and it is possible to respond with short delivery times. This method is ideal for cold plates with a thickness of 4 to 8 mm waterway lid structure, not limited to product size, and is mainly used for low melting point materials such as aluminum and copper.

Why we specialize in aluminum and/or copper cold plates joining in FSW?

- It is possible to join in the atmosphere and also both cost reduction of the products and shorter production periods by reducing setup time by the hybrid machine will be realized.

- To meet the demands from the customers who want to make trial products instead of brazing.

- To respond to multi-mixed and small-volume products for production manufacturing equipment, not large-volume production for final products such as automotive

- In order to ensure the product quality assurance , integrated production from machining to joining was necessary.

- Because FSW is a technology that can make use of the know-how of devising work clamps and jigs that machine shops are good at

The difference between our own FSW and vacuum brazing

| FSW | With vacuum brazing | |

|---|---|---|

| Atmosphere | The atmosphere | Vacuum |

| Facility | ※Hybrid | Vacuum furnace |

| Material | Aluminum, copper | A wide range of materials |

| Production | Multi-mixed small amount | Mass production |

※Cutting and joining are possible with the same equipment.

The difficulty of welding materials with high thermal conductivity

It is very difficult to join aluminum or copper with high thermoelectric rate by hand welding. Especially in case of the products that require high airtightness with a water-cooled jacket structure it can be unreliable.

When joining by hand welding (co-welding and brazing) in the atmosphere, preheating (usually 250 to 600 °C) by burner to the main material of which thickness is 6mm or more is required, depending on the size and thickness of the workpiece. Especially in the case of copper-to-copper bonding, oxide film (slag) is generated when heated, and welding by involving this slag is more likely to lead to defects such as high-temperature cracking of the joint point and blowholes (bubbles) being left inside the joint point.

Comparison with other methods

As for cold plate bonding with high thermal conductivity materials, the main methods for obtaining reliable bonding is vacuum brazing welding or electron beam welding in the vacuum atmosphere, and so far we have also used vacuum brazing and electron beam welding by cooperation companies , and will do so in the future, if necessary.

Vacuum brazing (advantages and disadvantages)

Vacuum brazing is ideal for bonding cold plates because it allows highly airtight bonding without melting the base material and especially it is possible to make the work surfaces adhere to each other. This method has been proven for a long time in the field of water-cooled heat sinks (cold plates). However, as a disadvantage of vacuum brazing, the entire workpiece is heated to 450 °C or higher to melt the wax material, so the overall workpiece is less resistant due to heat.It may not be suitable depending on the size of the product and the application of the product.

Electron beam welding (advantages and disadvantages)

Electron beam welding is ideal for large cold plates because the depth that can be joined compared to other bonds is overwhelmingly deep, and it is possible to join even between planks, and the thermal influence concentrates on the joint to ensure work strength. However, the disadvantage of electron beam welding is that gases generated from molten metal may be trapped as blowholes during solidification.