What is backing plates?

In thin film manufacturing of Liquid Crystal Panels and Semiconductors, a method of sputtering evaporates the metal and generates a circuit. The metal (target material) that evaporates when sputtering is very hot, so it cools and proceeds with the production process.

The backing plate is used to cool the target material.

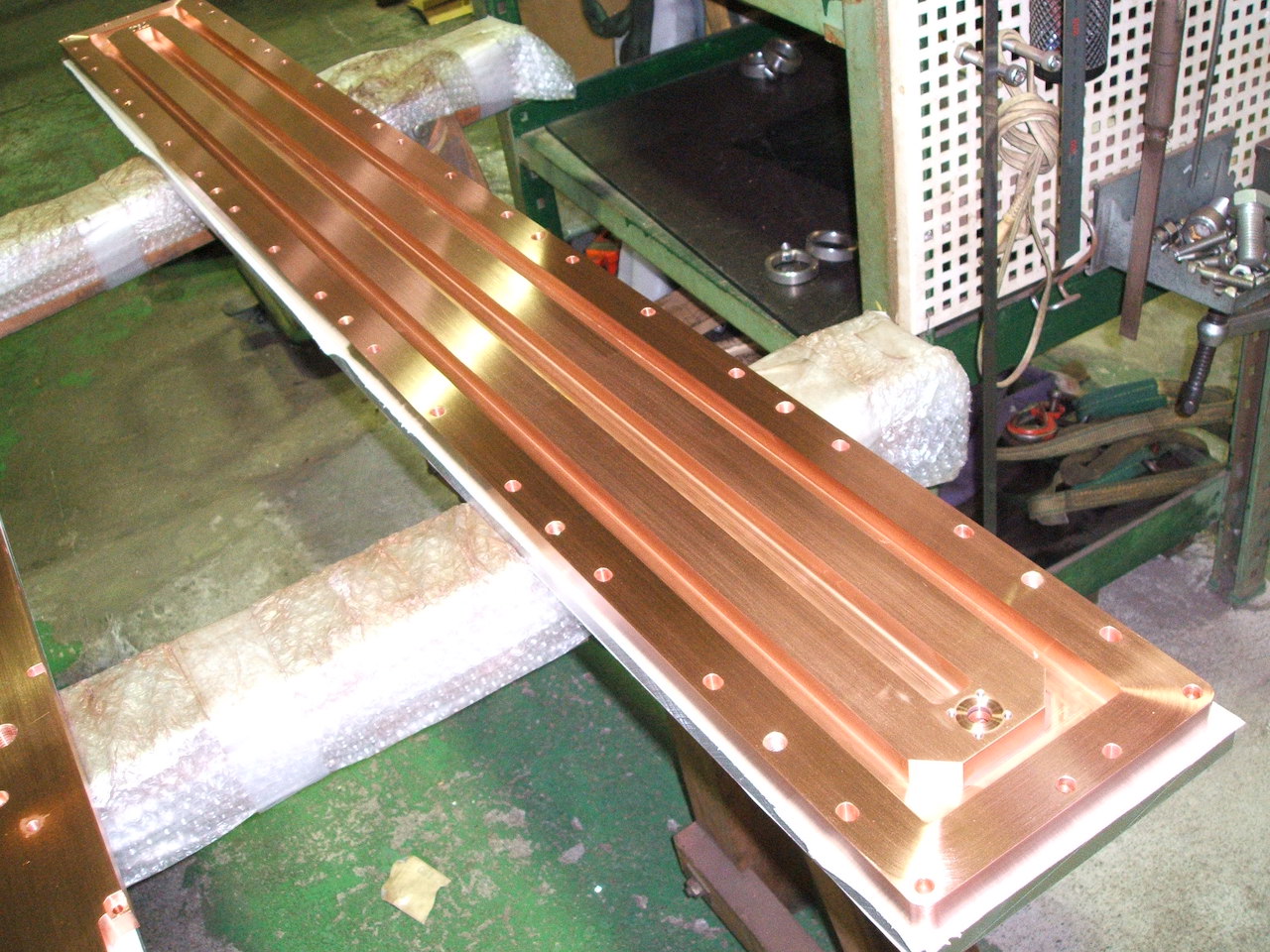

The backing plate is used in the vacuum chamber of the sputtering device, and the material is made of copper and has a water-cooled jacket structure.

Our backing plates

The water-cooled jacket is formed by joining the main body and the water-cooled lid with vacuum brazing, electron beam welding, Friction Stirring Welding, etc.

In particular, Friction Stirring Welding system of our own facility is considered to be more reliable at the junction than melt welding when it comes to bonding nonferrous metals, and is actually used for bonding the bodies of aircraft and Shinkansen trains.

Kyoyu’s backing plates respond to various types of shapes ranging from round to angular shapes, and advanced distortion correction technology enables surface cutting after welding to maintain a constant thickness of the water-cooled lid, contributing to improved cooling efficiency.

Production range

| Material | Aluminum, Stainless steel, Copper |

|---|---|

| Joining methods | Tig welding, Vacuum brazing, Electron beam welding (EBW), Friction stirring welding (FSW) |

| Maximum size that can be manufactured | Circular form:φ800mm Rectangular form:Width 1,000 mm、Length 2,000 mm |

| Structure | The jacket structure having grooves covering the lid from the above is main. |

| Shape | Compatible with various external shapes and complex waterway shapes |

| Specifications | All manufactured parts are custom-made with customer specifications |

| Notes | We do not provide purchasing, sales, or bonding services for target materials. |

Production examples

First, please feel free to contact us.

We can handle a wide range of services from technical consultation on product production and processing to consultation on specific estimates.